| Material: | Constantan, nickel chromium, zinc white copper, and other

copper-nickel alloys. |

| Structure : | Silicone single-core heating wire, silicone multi-core heating

wire, silicone single-core spiral heating wire. |

| Internal winding process: | Heating wire is wound on glass fiber or polyester wire. |

| Test standard: | UL758 related standards on heating wires. |

| Curve test: | More than 5000 times, no abnormality (test according to UL, IEC

test standards) |

| Bending test: | Less than 25,000 times, no abnormality (test according to UL, IEC

test standards) |

| Wire diameter range: | φ1.8~5.0mm

|

| Product life: | Above 10000H |

use:

Used for internal configuration cables of various high-end medical

equipment and communication cables of external medical equipment.

type:

1. There are various types of special-shaped wires such as round,

flat, square, etc.

2. The material is TPE, TPU, environmentally friendly PVC and other

covering materials.

3. The internal structure can be designed according to customer

requirements, using KEVLA or (Technora) aramid fiber to enhance the

performance of the wire.

Features:

1. High temperature resistance, corrosion resistance, dirt

resistance, easy to clean, novel and unique appearance.

2. Good insulation, strong conductivity, beautiful sound quality,

stable signal transmission, good anti-noise effect and strong

anti-interference.

3. The wire is soft, feels good and is not easy to tangle.

4. Small structure, novel appearance, easy to carry.

5. It has strong tensile strength, high swing times, strong ability

to withstand the invasion of chemicals such as gasoline, alcohol,

cosmetics, excellent weather resistance and long service life.

6. Comply with RoHS, REACH, California 65 standard and SONY-GP and

other related environmental protection requirements.

7. Reasonable structural design and the use of high-quality

materials make the product easier to peel and weld, with higher

reliability and processing type.

8. Can carry out supporting design and development according to

customer product characteristics and customer requirements.

Medical equipment transmission cables are high-performance wires or

cables designed specifically for medical devices, used for

transmitting data and electricity. They have the following

characteristics:

1. Safety:

Medical equipment transmission cables comply with strict safety

standards such as ISO 13485, CE marking, etc., ensuring the safety

of patients and operators.

2. Reliability:

These cables can withstand long-term use and repeated disinfection,

maintain stable performance, and ensure the reliable operation of

medical equipment.

3. Accuracy:

Medical equipment transmission cables maintain a high degree of

accuracy in transmitting data and power to meet the precise

requirements of medical equipment for signal transmission.

4. Corrosion resistance:

Due to the presence of disinfectants and other chemicals in the

medical environment, these cables have corrosion resistance to

prevent damage caused by chemical corrosion.

5. Environmental friendliness:

Medical equipment transmission cables usually comply with

environmental standards and do not contain harmful substances to

reduce their impact on the environment and patients.

6. Compatibility:

These cables need to be compatible with various medical devices,

including monitoring equipment, surgical equipment, imaging

equipment, etc., to meet different medical application needs.

7. Resilience and Durability:

Medical equipment transmission cables have a certain degree of

toughness and durability, and can adapt to stretching, bending, and

pressure in medical environments.

In short, medical equipment transmission cables are an important

component of medical equipment, and their design and manufacturing

need to meet strict quality and safety requirements to ensure the

normal operation of medical equipment and the safety of patients.

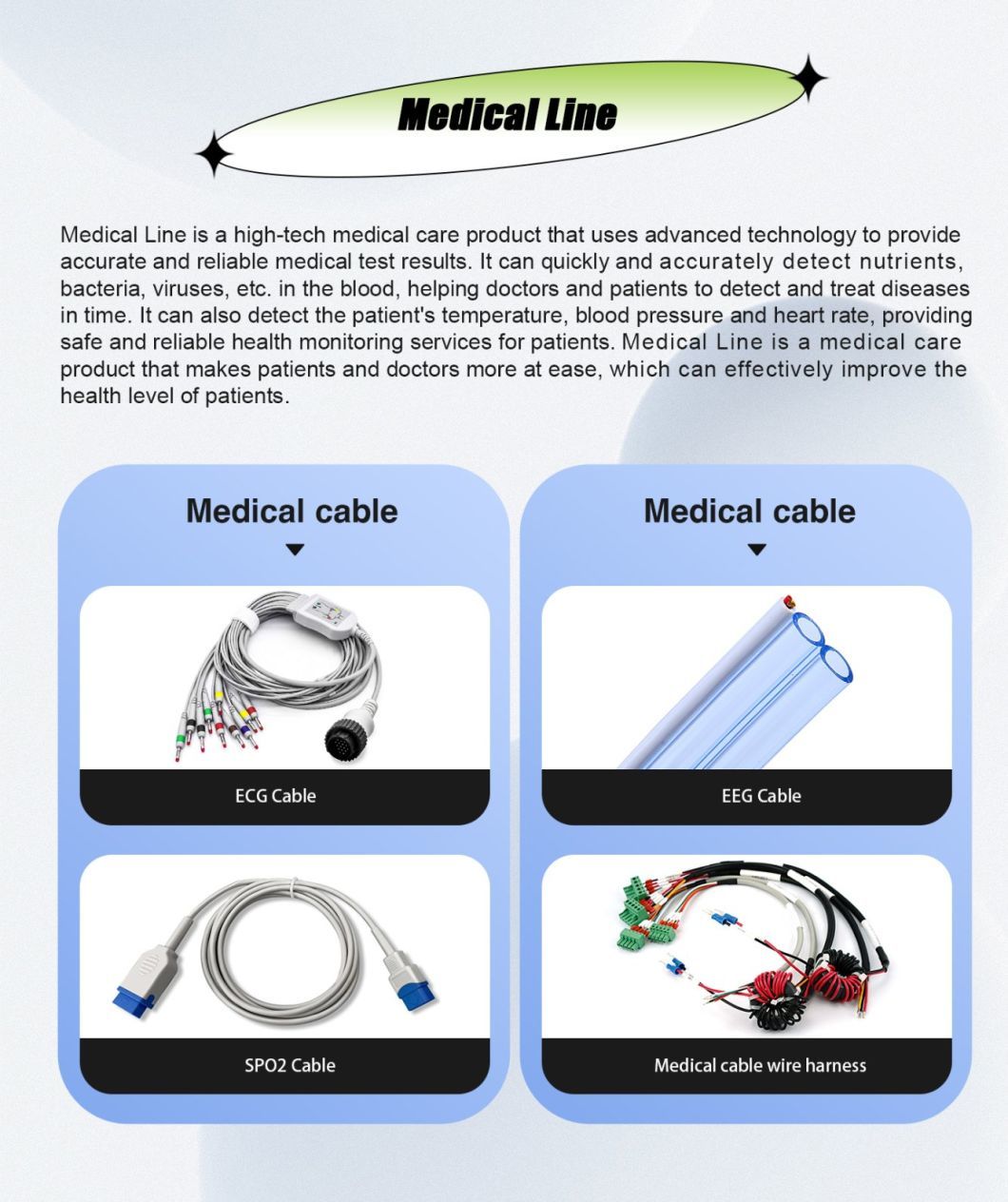

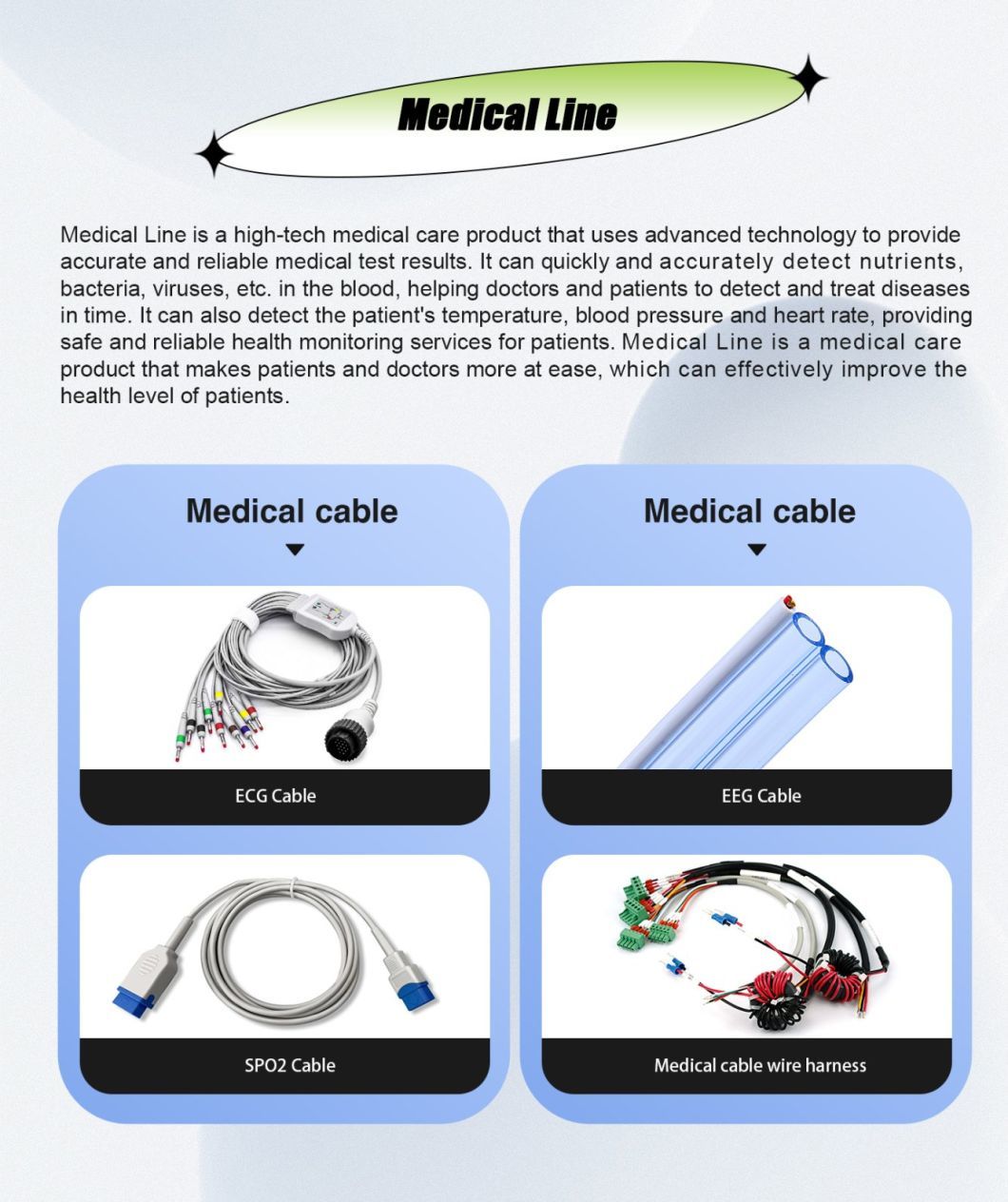

Medical cable refers to a type of cable specifically designed and

used in medical applications. These cables are used to transmit

signals or power in various medical devices and equipment, such as

diagnostic imaging machines, patient monitoring systems, surgical

instruments, and medical sensors. Medical cables are constructed

with materials that meet the strict regulatory requirements and

standards for medical equipment. They are designed to provide

reliable and accurate transmission of electrical signals or power

while ensuring patient safety and compliance with medical device

regulations. These cables often have specialized features to

withstand the unique environmental conditions encountered in

medical settings, such as resistance to sterilization processes,

flexibility for easy routing, and shielding to prevent interference

from external sources. Overall, medical cables play a crucial role

in ensuring the proper functioning and safe operation of medical

devices, connecting various components within the medical equipment

and facilitating the transmission of vital information for

diagnosis, treatment, and patient monitoring.

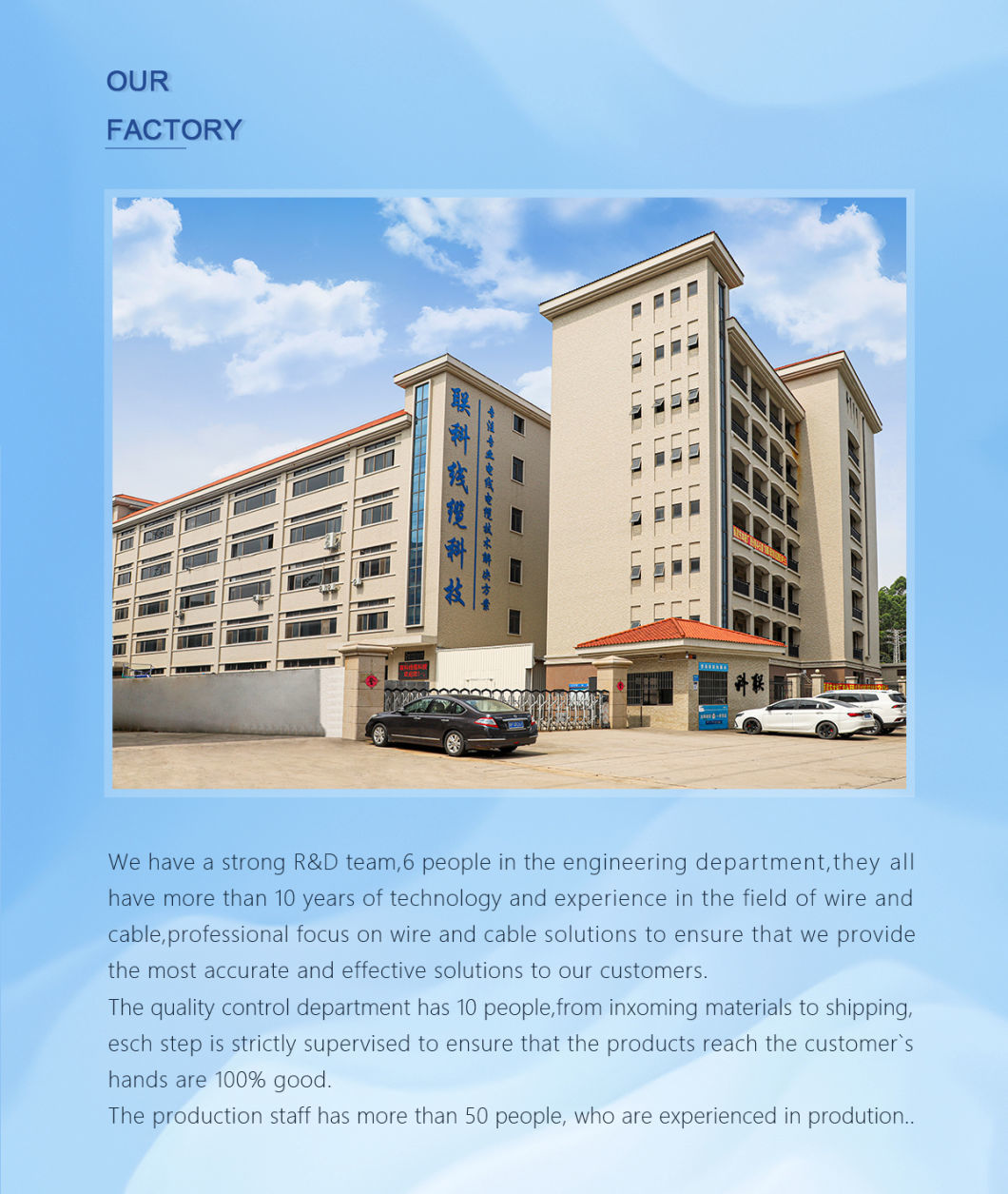

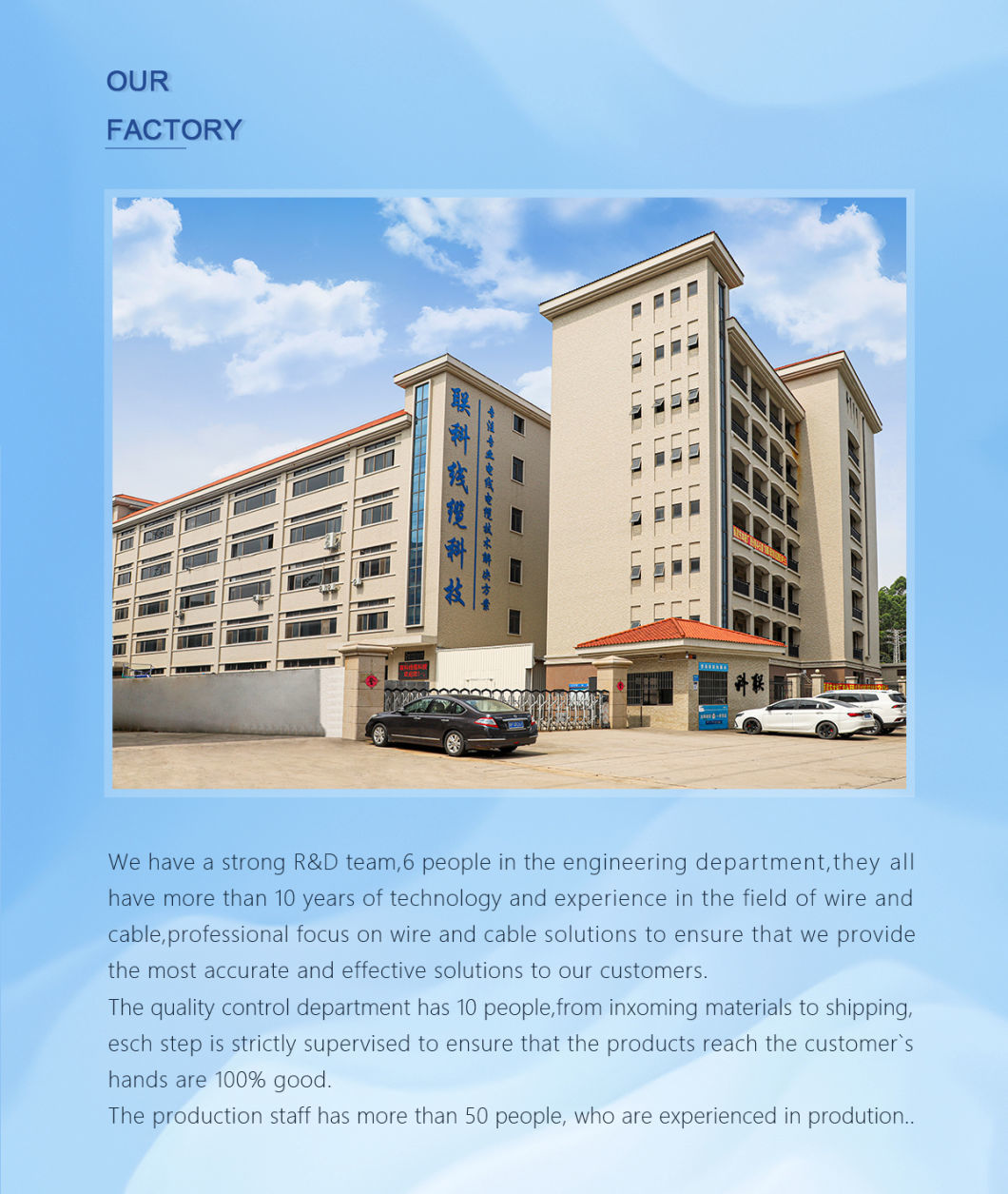

Company Profile:Wire and cable manufacturer Linke Cable Technology Co., Ltd is a

leading cable supplier in China. In the past over 10 years,

Linke Cable has been focusing on R&D, production and marketing

of wire and cable. Linke provide various cables&custom

cable solutions for all over the world. We are specialized in EV

charging cable, medical cable, silicone cable, spring cable,

braided cable, towlobe cable, UL wire, automotive cable, etc.

At Linke cable, we believe there's a better way to bring better

cables to market. We use an engineer-to-engineer approach

to develop better cables for customers and improve the quality of

one's life.

1. Are you a manufacturer or trading company?

We are a professional manufacturer. We can control your order from

the first begining to the last.

Welcome to visit us. We'll pick you up in Shenzhen.

2. How can I get a sample to test your quality?

The samples are free for you. New clients are expected to pay for

the courier cost.

3. What's your Minimum Order Quantity?

Normally 100m. However, the cable is very heavy.

You'd better order a suitable quantity to avoid the high freight.

Sea transportation is the best option.

4. Can I get a discount?

It depends on your quantity, We can make a discount and afford the

freight. Pls kindly contact us.

5. Does your company accept OEM production?

Yes, could print your company name, we even custom the quality card

to promote your company